If you read our previous article about aluminum grating, I’m sure you know about grating roughly. But in fact, aluminum grating is also divided into different types based on processing. Among them, the swaged grating is a grating product that combines strength, durability, and style. But what exactly is it and why does it occupy an important position among aluminum grating? Let’s enter the world of swaged grating and discover its secrets.

Understanding the background of swaged grating

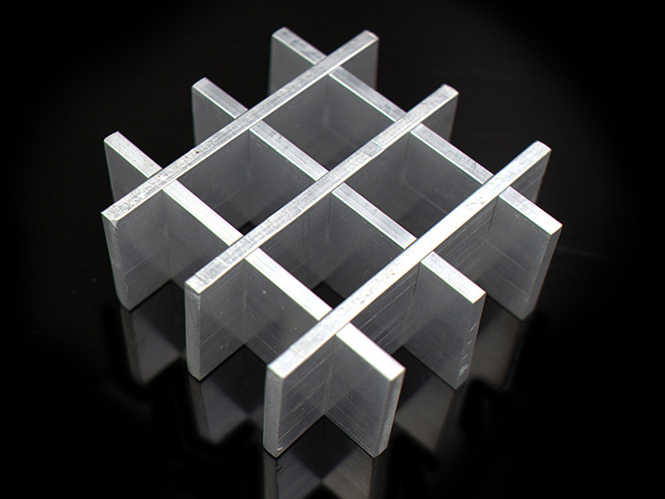

Swaged grating is a type of aluminum grating manufactured through an extrusion process. This process deforms the aluminum bars under high pressure to create a strong bond between the bars and the carrier. The swaged aluminum grating produced in this way is not only aesthetically pleasing but also very strong and durable.

How swaged grating is manufactured

First, the aluminum needs to be liquefied in a casting furnace, which then goes into a die to extrude the profile. Afterward, it is allowed to be straightened by a traction machine and then insulated to form flat aluminum. When the flat aluminum is finished, it can be processed, after punching teeth, punching holes, and swaged using an extruder. After this, the aluminum is cut to the required size and then surface-treated.

Specifications of HY Industries’ swage series aluminum grating

Welcome to HY Industries’ swage product line, where innovation and durability go together. Our swaged grating embodies engineering excellence, designed to meet the needs of a wide range of applications including architectural and industrial. Our aluminum grating solutions focus on strength, safety, and aesthetics, perfect for projects that demand high performance and reliability.

Swaged grating key features

No welding points: Our aluminum grating is uniquely designed with no welding points to ensure strong connections and greater structural integrity.

Lightweight and Strong: Our swaged grating is constructed from premium aluminum, which is lightweight and strong, making it easy to handle and install without sacrificing durability.

Corrosion Resistant: Aluminum’s natural resistance to corrosion makes aluminum grating ideal for outdoor and industrial environments where exposure to the elements can be dangerous.

Americans with Disabilities Act Compliant: Our grating products are compliant with the Americans with Disabilities Act (ADA), providing a safe and accessible walking surface for all users, including those in wheelchairs and high heels.

Aesthetically Pleasing: We offer a variety of finishes for the grille surface, including glossy, natural color anodized, and powder coated. This, coupled with wood and stone grains, can add a unique style to a building and meet architectural design requirements.

Applications

Swaged grating is versatile and can be used in a wide range of construction projects, including

Industrial facilities: Durable, safe walkways, treads, and decking solutions for factories and warehouses.

Commercial spaces: to enhance the aesthetics and functionality of building facades, ventilation grilles, etc.

Public projects: Ideal for pedestrian bridges, gutter covers, and fencing to ensure accessibility and durability.

Educational and healthcare facilities: Reliable, low-maintenance walkway and railing options for high-traffic areas.

Product types

HY Industries offers various types of swaged aluminum grating to meet the specific needs of your project:

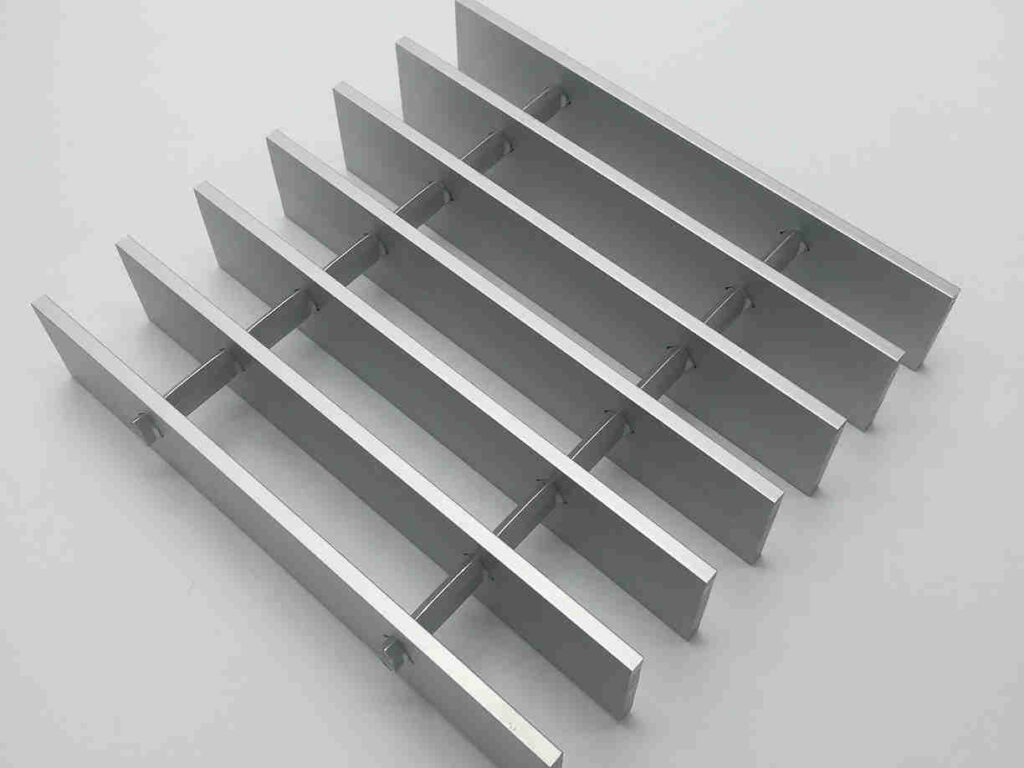

Rectangular grating: Known for its simple and effective design, it is one of the most widely used products. Scenarios include building facades, fences, treads, and walkways and are available in a variety of spacings.

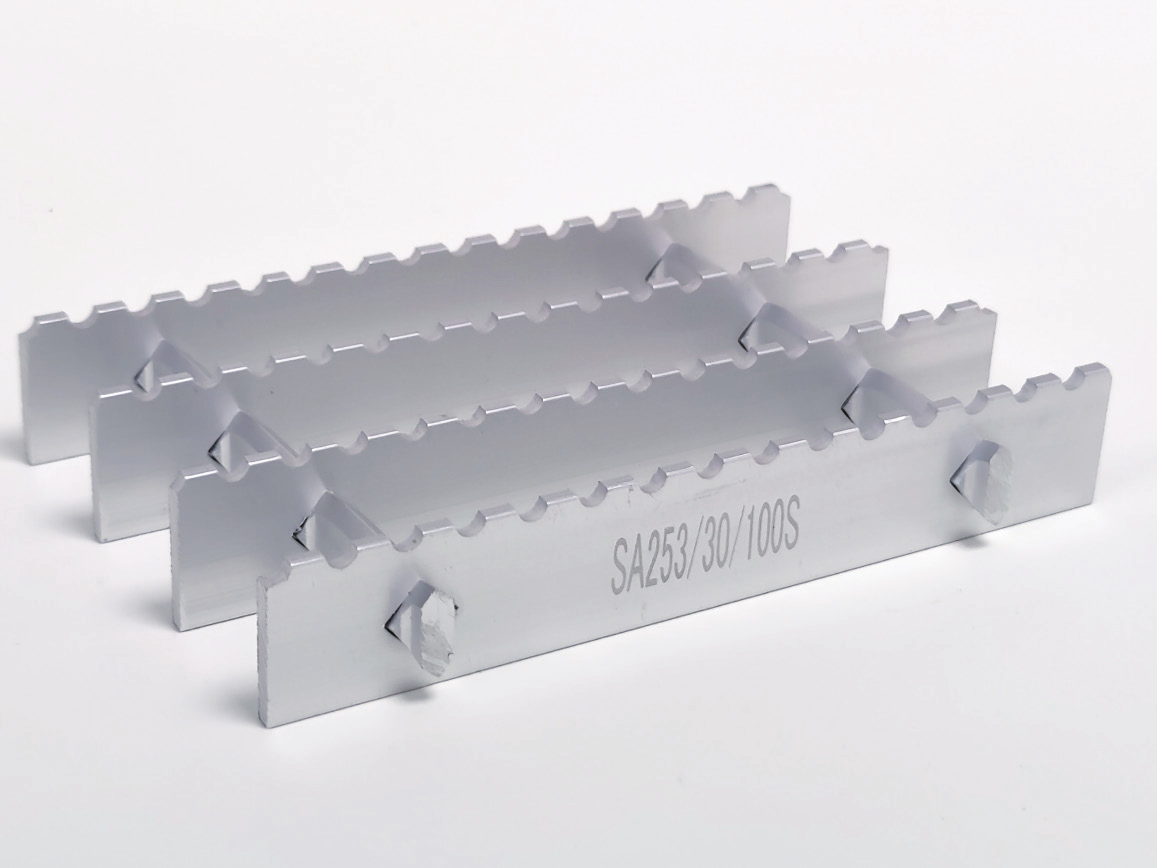

Serrated grating: The edges have a unique serrated surface that enhances anti-slip properties. Ideal for areas with high safety requirements, such as safety walkways and platforms.

I-bar grating: Lighter in weight than rectangular grating, it also has a serrated finish on the top and bottom surfaces for enhanced slip resistance. It is also available in an ultra-small pitch of only 11.1mm, which prevents heel catching and improves safety.

T-bar grating: This shape provides a larger contact surface for improved comfort when stepping. Provides a strong, stable surface with excellent load-bearing capacity.

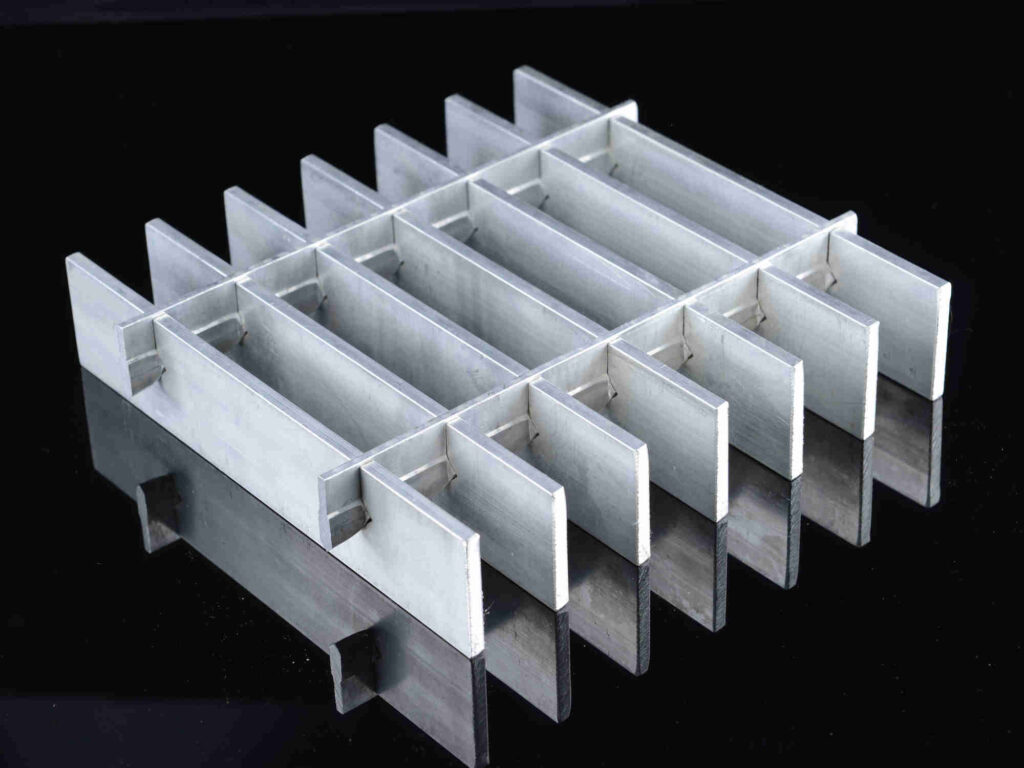

Flat top grating: A combination of diamond-shaped square and flat aluminum surfaces are flush together to provide a unique look while enhancing the load-bearing surface.

Press-lock grating: Secured by press-locking for greater load-bearing capacity and suitable for demanding industrial or commercial environments.

Conclusion

In short, the world of swaged grating is vast and fascinating. From the manufacturing process to the many applications and benefits, this grating plays an important role in modern infrastructure. At HY Industries, we are committed to providing quality aluminum grating products that not only meet but exceed your expectations. Explore our range of aluminum grating products to find the perfect fit for your architectural and industrial needs.