Have you ever walked on a sturdy metal floor in a factory or industrial site and wondered what material it was made of? Most likely, it was bar grating that you stepped on. This sturdy and practical building material can be used in various projects. Bar grating can be divided into several different types. Let’s start with some basic information about this material before we dive into the details of the various types of bar grating.

What is bar grating?

Bar grating is a grid-like structure consisting of parallel strips of metal, spaced between materials and connected by vertical cross bars. This design creates a strong, durable, lightweight flooring option that can be used in a variety of settings, from industrial factories to bridge decks. It comes in a variety of types, each with its unique benefits and applications.

Steel bar grating

Firstly, there’s steel bar grating. It is usually made of carbon steel with a hot-dip galvanized exterior, which can serve to prevent oxidation, or it can be made of stainless steel. This type of steel grating is commonly used in industrial environments with heavy loads and harsh conditions. Examples include factories, warehouses, and walkways where there is heavy equipment and foot traffic.

There are several types of welded steel bar grating, including pressure-welded, inlaid, and through-locked and through-welded types. Welded steel grating, as the name suggests, is welded at the joints and is therefore very strong. Compression-locked grating, on the other hand, is made by pressing the cross bars into the carrier bars under pressure, creating a tight bond without the need for welding. Press-locked steel grating uses a crimping process to lock the cross bars into the supporting bars, giving it a neat and uniform appearance.

One of the outstanding features of steel bar grating is its load-bearing capacity. It is very suitable for places with large traffic flow, such as sports stadiums, exhibition centers, shopping malls, and so on.

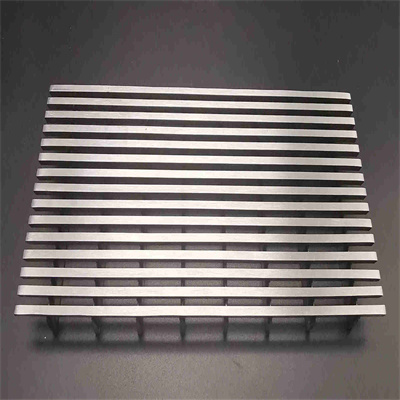

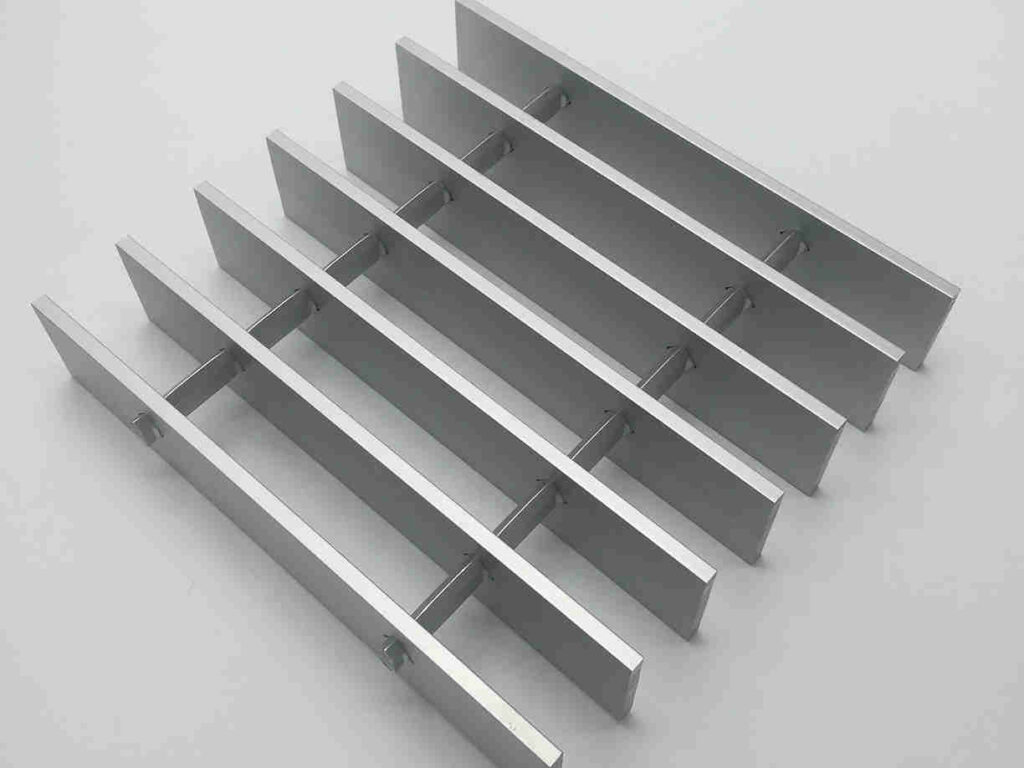

Aluminum bar grating

Now, let’s talk about aluminum bar grating. Compared to steel bar grating, aluminum is lighter and more flexible, but still very strong. Aluminum bar grating would be made from a high-quality aluminum alloy that is known for its corrosion resistance and lightweight. This makes aluminum grating the best choice for environments where corrosion is a problem, such as coastal areas or chemical plants.

One of the biggest advantages of aluminum bar grating is that they are easy to install. Because it is lighter than steel, they are easier to handle during installation and can reduce labor costs. This makes it a favorite for projects that need to be completed quickly and efficiently. Additionally, aluminum bar grating can be finished in different finishes such as anodized, powder coated, and woodgrain making it more unique and aesthetically pleasing to meet architectural design needs.

Apart from being suitable for coastal areas, it is also an excellent choice for building facades and shop decoration. Plus aluminum is highly recyclable and one of the few materials that can be 100% recycled, making it a more environmentally friendly choice.

Galvanized bar grating

Next to be introduced is galvanized bar grating. This type of bar grating mainly refers to a layer of zinc plated on the metal to prevent corrosion. The main method used is hot-dip galvanizing.

Galvanized bar grating is ideal if the site of use is outdoors or within a chemical plant. This includes all applications from rain gutters and gutter covers to decks and stair treads. The zinc coating provides long-lasting protection, ensuring that the grating remains durable and functional even in harsh weather conditions.

One of the major advantages of galvanized bar grating is its ability to maintain the strength of the metal material while enhancing the benefits of corrosion resistance. This makes it a versatile choice for industrial and commercial applications.

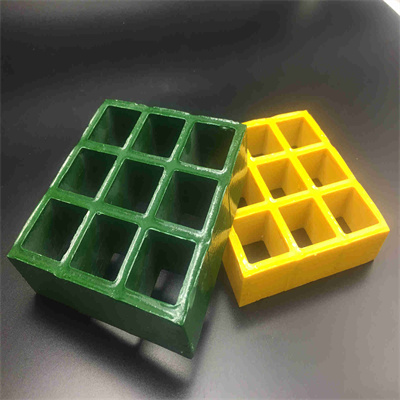

Fiberglass bar grating

Last but not least is fiberglass bar grating. If steel and aluminum are the traditional protagonists of bar grating, fiberglass is the new material with a modern touch. It is made from a composite of glass fiber and resin and offers unique advantages over metal grating.

Fiberglass bar grating is very lightweight, even lighter than aluminum. It is also non-conductive, making it a safe choice for electrical and high-voltage environments. As a result, fiberglass grating can often be found in places where safety is paramount, such as power plants, chemical processing facilities, and marine applications.

Another outstanding feature of fiberglass grating is its resistance to corrosion and chemicals. Unlike steel bar grating, which can rust or corrode over time, fiberglass grating is unaffected by moisture, salt water, and many chemicals. Therefore, it is the best choice for harsh or corrosive environments.

Fibreglass grating is lightweight and easy to cut, so there is no need for heavy machinery or special tools to install it, which can save time and money. These materials are available in any color, with custom colors to match the design.

Conclusion

Choosing the right material for bar grating for your project can be a decision that consumes a lot of your time, but it doesn’t have to be. By understanding the unique benefits and applications of steel, aluminum, galvanized, and fiberglass bar grating, you can make an informed decision that meets your specific needs.

Steel bar grating offers unrivaled strength and durability, making it ideal for heavy-duty industrial applications. Aluminum bar grating is lightweight and corrosion-resistant, making it ideal for projects that require both strength and aesthetics. Galvanized steel grating combines the robustness of steel with greater corrosion resistance for outdoor and harsh environments. Fiberglass bar grating offers modern, high-tech benefits, including non-conductivity and chemical resistance, making it a safe and versatile choice.

At HY Industries, we offer a wide range of grating materials including aluminum bar grating, steel bar grating, and FRP bar grating. All are manufactured in HY factories with advanced technology and machinery. Besides material production, we also provide full architectural services for project design, site survey installation, and construction. If you are interested in or have questions about the services offered by HY Industries, please contact our customer service team by email or online.