We’ve presented you with a comparison of many metal grating materials before, but new grating material has become a trendy option. That’s FRP grating, so when choosing the right grating for your project, you’ll be faced with a critical decision: fiberglass grating or steel grating. Each option has its unique benefits and applications, much like picking the right tool for the job. Let’s dive into the world of steel grating and explore the diversity between fiberglass and steel grating.

What is FRP grating?

FRP grating is a new type of material, a kind of glass fiber as reinforcing material, with unsaturated polyester resin as the substrate, after special processing composite becomes a kind of plate material with many spaces. Compared with other metal grating with rectangular spaces, its spaces are square.

Characteristics of this type of grating

Lightweight

The density of FRP is about 14-21kN/m3, which is about 1/6~1/4 of steel, and even lighter than metallic aluminum.

Corrosion resistance

Like aluminum grating, FRP grating is known for its corrosion resistance, making it ideal for environments that require exposure to chemicals or moisture. It ensures safety in wet or greasy environments.

Non-conductive

This means it’s safe where electricity is present. Excellent electrical insulation with no breakdown at 10KV; non-electromagnetic and can be used on magnetically sensitive equipment.

Multiple colors

FRP grating can be manufactured in a wide range of colors and can be selected and matched at will to meet different design needs.

Areas of application

FRP was first used in aerospace and military applications. Later, as the cost of the material decreased, FRP began to appear in ordinary life as a construction material.

FRP grating can be found in industries such as chemical processing, food and beverage, water treatment marine environments, walkways, and operating platforms. Its corrosion resistance and low-maintenance requirements make it ideal for use in places where traditional materials would be difficult to perform.

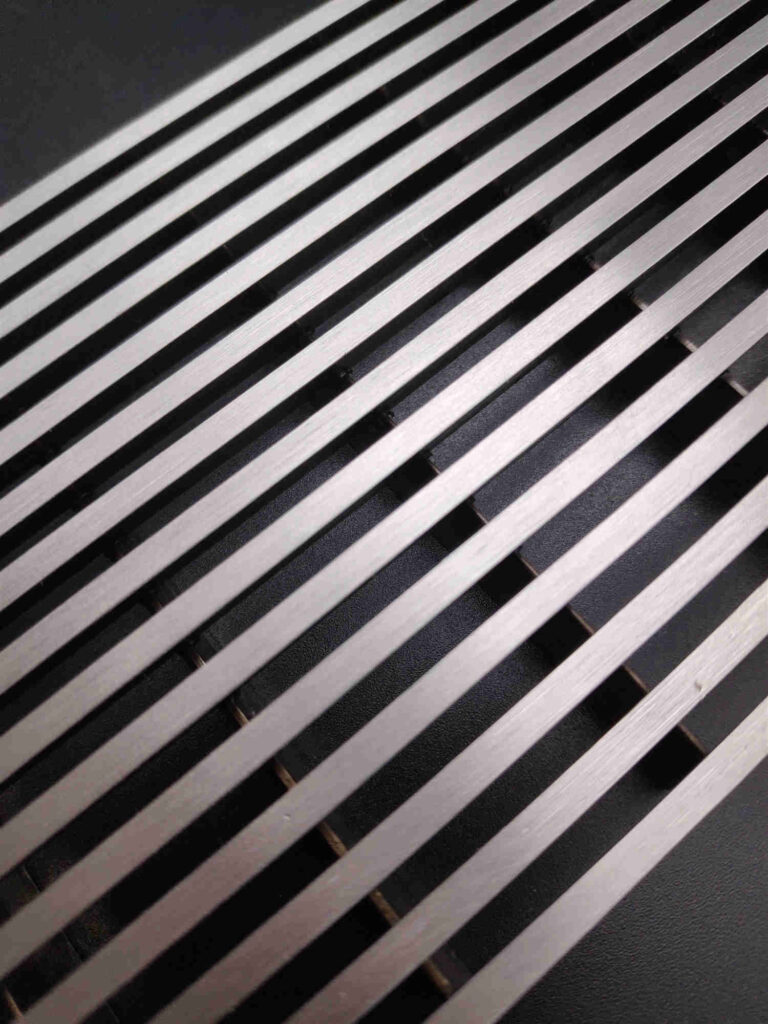

What is steel grating?

Steel grating is made of carbon steel or stainless steel, with flat steel according to a certain spacing and crossbar for cross-arrangement, and welded into the center with a square lattice of a kind of steel product. The appearance can be divided into flat grating, serrated grating, and I-bar grating.

Characteristics of this type of grating

High strength

Steel grating can withstand heavy loads and tremendous pressure. As a result, steel grating is ideal for industrial environments where strength is critical.

Durable

Steel grating is durable and will last a long time, even under harsh conditions.

However, it is susceptible to corrosion if not treated properly. Galvanizing or coating helps protect it from environmental damage, extending its life and maintaining its structural integrity.

Areas of application

Steel grating is commonly used in manufacturing, oil and gas, construction, and transportation industries. And you can see this material in settings like sidewalks, decks, stair treads, and drainage covers.

Differences between FRP grating and steel grating

Now, let’s compare these two contenders and see how they stack up.

Weight and installation

Fiberglass grating panels are much lighter than steel panels, making them easier and less costly to transport and install. This saves time and reduces labor costs, especially on larger projects. Steel grating is heavier but has unrivaled strength, making it suitable for areas with high load-bearing requirements.

Corrosion resistance

Fiberglass-reinforced plastic grating wins when it comes to corrosion resistance. It won’t rust or be damaged by chemicals, making it ideal for harsh environments. Steel grating requires a protective treatment to resist corrosive elements, which can increase maintenance costs over time.

Conductivity

Fiberglass does not conduct electricity, making it safer to use in areas with electrical hazards. Steel, on the other hand, is a conductor and requires careful consideration and additional safety measures in electrically sensitive environments.

Cost

Initially, FRP grating may be more expensive than steel grating. However, in the long run, FRP grating saves money with its low maintenance needs and long service life. Steel grating may have a lower upfront cost, but may incur higher maintenance costs due to the need for corrosion protection and repairs.

Environmental impact

Fiberglass-reinforced plastic (FRP) grating is often seen as more sustainable due to its long service life and low maintenance. Steel grating, while recyclable, has a higher environmental impact due to the large amount of energy consumed in its production process.

FRP grating from HY Industries

HY Industries has decades of experience in the production of grating materials as well as high-end production equipment and independent factories. FRP grating is also one of HY’s popular products and can be customized to meet design needs, from color to size.

HY Industries’ commitment to innovation ensures that their FRP grating solutions are at the forefront. Whether you are dealing with corrosive environments or need a lightweight, robust option, HY will provide reliable solutions suited to your needs.

Conclusion

When making your final choice you need to know that it will depend on your specific needs and working environment. Fiberglass grating offers excellent corrosion resistance, safety, and ease of installation, making it ideal for many applications. Steel grating offers unmatched strength and durability and remains the preferred choice for heavy-duty industrial applications.

Both materials have a place in construction and industry, each with its advantages. By understanding the unique qualities of each material, you can make an informed decision that best suits your project’s needs.

At the end of the day, whether you choose the lightweight resilience of fiberglass or the rugged strength of steel, the material you choose will support your work and contribute to a safer, more efficient environment.