Platforms made from grating may not be something you think about daily, but they play a vital role in many industries. Whether securing a factory, providing a flat surface for a bridge, or a stable walkway in a park, grating platforms are everywhere. So what exactly are grating platforms and what types are there? Let’s break it down to help you understand their importance and how to choose a grating platform of the right material for your needs.

What are grating platforms?

Firstly, you need to understand what a grating is. This is a metal material made from different metals arranged crosswise at certain spacing and crossbars, which are welded into a metal material with a square lattice in the middle by a press welder or by hand.

So a grating platform is a surface made up of grating bars typically used to provide a strong, durable, and non-slip walking or working surface. These platforms are designed to support weight while allowing for drainage and ventilation.

Grating platforms come in handy in many situations. They are commonly found in industrial environments such as factories and warehouses where safety and durability are paramount. But in recent years these platforms have also begun to appear in commercial spaces, public areas, and residences. The open grid design helps to prevent standing water, oil, or debris and reduces the risk of slips and falls. Now, let’s take an in-depth look at the different types of gridded decks and their features.

Steel grating platform

Steel grating platforms are usually made of carbon steel or stainless steel with a hot-dip galvanized surface to prevent oxidation. Steel grating is widely used in many fields, such as petrochemical, electric power, water, sewage treatment, harbor terminals, building finishing, and so on.

Characteristics

Steel is a metal with a variety of properties, including high strength, less prone to dirt accumulation, easy maintenance, good ventilation, lighting, heat dissipation, and anti-slip and explosion-proof properties.

However, a hot-dip galvanized surface is required to obtain good corrosion protection.

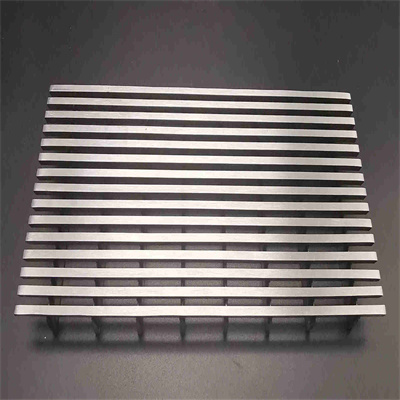

Aluminium grating platform

Aluminum grating is usually made from high-quality aluminum alloys and is available in a wide range of sizes and finishes. There are also different options in exterior finishing processes. The aluminum grating has many applications and is commonly used in building facades, pedestrian walkways, bridge decks, and other occasions. It not only has a good decorative effect, but also provides good ventilation performance, improves the visual effect of the space, and makes the space appear more spacious and bright.

Characteristics

Aluminum grating is less dense and lighter. In the case of the same volume, the weight is only one-third of steel. Aluminum material itself has a strong corrosion resistance and can resist acid and alkali, organic solvents and salts, and other media erosion. And has a high impact strength, and can withstand repeated use without permanent deformation.

What’s better is that this material can be 100% recycled, in line with the requirements of green environmental protection. Thanks to these excellent properties, aluminum grating platforms can still be used for many years, even in harsh outdoor weather.

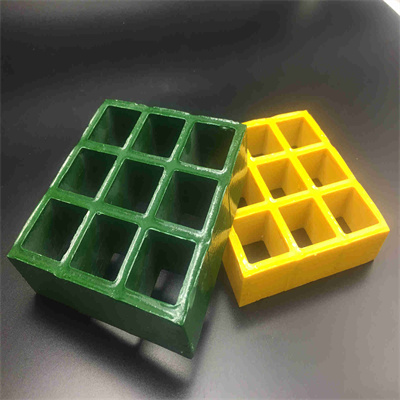

FRP grating platform

FRP grating or fiber-reinforced plastic grating is a kind of sheet with many spaces made of glass fiber as reinforcing material and unsaturated polyester resin as a matrix. Besides being used as a platform material, it can also be used for maintenance walkways, flow troughs, operating platforms, etc. that need to have good corrosion resistance.

Characteristics

FRP grating certainly has very superior corrosion resistance to acid, alkali, organic solvents, and salts. It is also less dense and the lightest of the three materials, being only 1/4 of steel and 2/3 of aluminum, making it much simpler to install and saving a great deal of installation costs. This, combined with its flame retardant and electrically insulating properties, makes it one of the materials that offers great safety. The properties of the material allow it to be customized in colors to suit the design needs of the customer.

Which is better for you?

Choosing the right grating platform depends on your specific needs and the environment in which it will be used. Before choosing a specific material, please refer to the following introduction:

Steel grating platform: If you need maximum strength and durability for heavy industrial use, then steel grating is the way to go. It is ideal for heavy loads and severe wear and tear.

Aluminum grating platform: If weight, corrosion resistance, and cost are your primary considerations, especially in marine or chemical environments, aluminum grating is the way to go. Its modern appearance also makes it more suitable for architectural applications.

FRP grating platform: If you need a lightweight, corrosion-resistant, non-conductive product, FRP grating is the best choice. It’s perfect for environments where traditional materials would fail and has the added benefit of being easy to handle and install.

When making your decision, consider factors such as your project’s load requirements, environmental conditions, and maintenance needs. Each type of grating platform has its advantages and can excel in specific situations.

Conclusion

Grating platforms may not be the most glamorous part of many construction projects. But it is vital in ensuring safety, durability, and efficiency. Whether you choose the robustness of steel, the lightweight corrosion resistance of aluminum, or the innovative benefits of FRP, each type of grating platform has its unique advantages.

It’s worth noting that whichever you choose, HY Industries can provide it. That’s because HY has a factory that produces quality construction materials. Furthermore, if you want to build a grating platform, HY can complete the project from all aspects, including design, production of materials, and installation. Feel free to contact our team for the latest material information and quotes.