Image punching board

Image Punching Board

As a new era product, image punching boards (perforated panels) are becoming more and more popular among customers, especially image punching boards that can freely customize patterns. Its appearance is gorgeous and connotative, and it can be used as home interior decoration or exterior wall decoration. Image-type punched panels can be applied to the exterior walls of major commercial buildings and have powerful functions such as sunshade, decoration, protection, sound insulation, and pollution control.

Image punching board

Technical parameters of perforated plate

Swage and Expanded Technology and Process:

Thickness: Popular thickness: 2-12mm. However, Haiyue Industry can drill holes up to 25mm thick according to special requirements, with hole sizes ranging from 2mm to 154mm.

Board size: Standard sizes include 2mx1m, 2.5mx1.25m, and 3mx1.5m. We can also drill a hole of 4mx2m on one of the larger machines. According to special requirements, longer lengths up to 6m can be perforated.

Percentage open area: All open areas are physically possible. Standard tools often range from 20% to 60%.

Haiyue Industrial punching plate fully complies with OSHA standards!

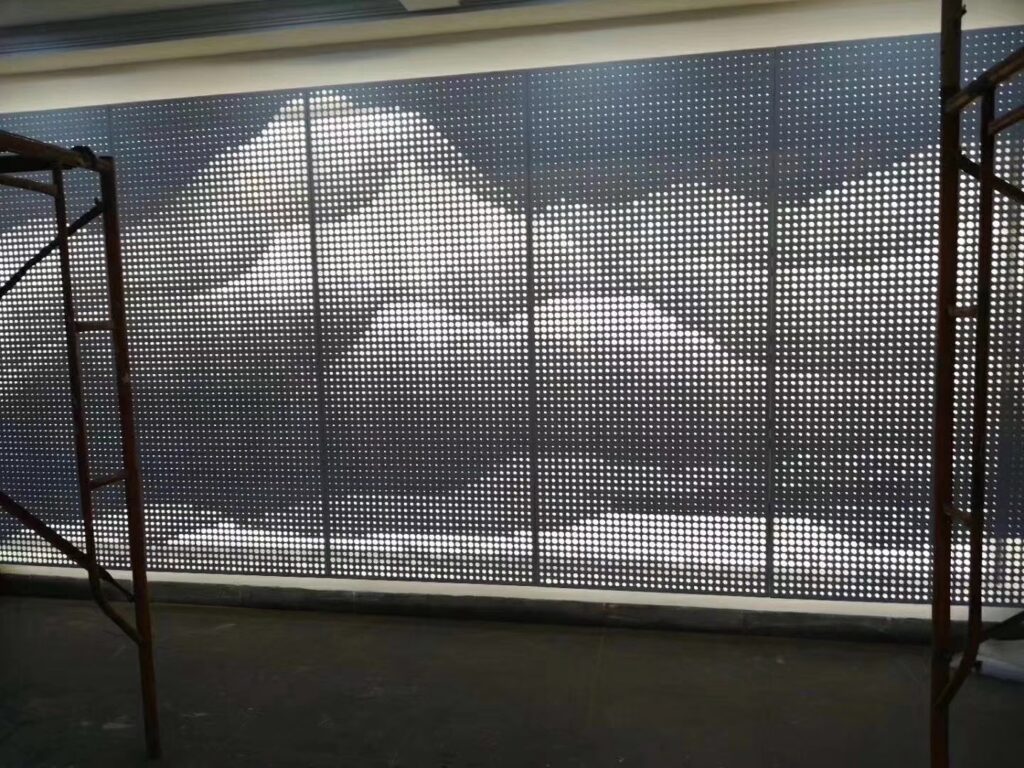

Image perforation

Picture perforated plate range to create images and artistic picture patterns in your project designs. Re-create the image using advanced design software and engineering to re-model the desired image using different hole sizes and hole locations. The image can be modeled to fit a low-resolution or high-resolution scene, depending on where the perforated panel is viewed from. Our proprietary fixing solutions mean Muse® Picture perforated panels can be fixed to structural steel, aluminum framing, or masonry depending on your project requirements. Perforated panels can be anodized or powder-coated.

Ideal for artwork solutions, car park facades, balcony screens, privacy screens, feature screens, facades, sun shading, and walkways.

Image perforation

The image perforated plate, through changes in aperture and hole spacing, has grown plants from the punching plate, while the overall material remains fresh over time, demonstrating its weather resistance and self-cleaning ability in natural environments. Aluminum alloy materials also effectively embody the concept of time conveyed by the pattern.

Color Range

Our aluminum top rails are powder coated in various RAL colors. This powder coating can be made of nylon and polyester materials, among which nylon has excellent chemical resistance and can provide the highest level of wear resistance, making it the preferred application. Polyester fiber has weather resistance and UV resistance, and has better color stability than nylon, while nylon fades faster when exposed to sunlight for a long time. Neaco can achieve customized RAL colors because we have our own internal powder coating factory. The powder coating gives the railing a satin smooth surface, which is non shattering, permanent, wear-resistant, and wear-resistant.

Send us message

- 647-829-8288 | +61 433 916 063

- Mon - Sun 8.00 Am - 9.00 Pm

- 19 Clapham Rd,Regents Park,NSW,Australia,2143